Barrel

Why Choose Us

Rich Experience

Kotler has been engaged in the plastic machinery industry for more than 10 years, specializing in the production of plastic molding, wear-resistant and corrosion-resistant screw tubes for extruders, and special components.

Wide Product Range

Mainly used in the production of connectors, connectors, automotive precision components, optics, mobile phones, computers, precision gears, medical, special wires, plastics involving high temperature, high pressure, high corrosion, high wear PEEK, PPSU, LCP, PA46, PA66, PA4T, metal powder, neodymium iron boron, stainless steel powder, thermosetting BMC, bakelite, liquid silicone, optical PC, PMMA, etc.

Professional Technical Team

Kotler has an excellent team of professional design, R&D, manufacturing, sales and fast after-sales support, especially the designers who are proficient in the characteristics of various plastic raw materials, molding processes, molds and the characteristics of famous brand molding machines around the world. From customer consultation to design, quotation, manufacturing, installation and commissioning, we provide customers with one-on-one services!

Reliable Product Quality

Screw materials are purchased from Japan and Europe to ensure quality. We have independently developed HIP hot isostatic pressing sintered components and special centrifugal casting bimetallic barrels. the products of Kotler have passed ISO9001 quality management system certification.

The barrel of an injection molding machine, sometimes referred to as a cylinder, is the component that stores and heats the plastic before it is injected into the mold. It is commonly made from stainless steel or other alloys. The barrel consists of a long cylindrical chamber with several sections: the feed hopper, heating section, and nozzle. The feed hopper introduces the plastic pellets into the heating section, where they are melted. The molten plastic then passes through a runner system before entering each individual cavity in the mold to form the final product.

Importance of the Plastic Injection Molding Barrel

Melting and Homogenization of Plastic Materials

The primary function of the injection molding barrel is to melt and homogenize the plastic materials. As the plasticizing screw rotates within the barrel, it generates heat through friction, melting the solid plastic pellets or granules. The barrel’s internal heating elements provide additional heat as needed, ensuring complete melting and homogenization of the plastic material and eliminating any inconsistencies or unmelted particles.

Mixing and Dispersion of Additives

In addition to melting the base plastic material, the injection molding barrel facilitates the mixing and dispersion of various additives. Additives such as colorants, reinforcing agents, flame retardants, and lubricants are often incorporated into the plastic material to enhance specific properties. The barrel’s design and internal geometry, along with the rotation of the screw, promote thorough mixing and dispersion of these additives, ensuring uniform distribution within the melted plastic.

Temperature Control and Stability

The plastic injection molding barrel features precise temperature control mechanisms. Heating elements embedded in the barrel maintain the desired temperature profile for effectively melting and processing the plastic material. Proper temperature control is crucial for preventing overheating or underheating, as it directly affects the viscosity, flow, and quality of the molten plastic. Stable and consistent temperature control within the plastic injection molding barrel ensures reliable processing and optimized part quality.

Abrasion and Corrosion Resistance

The plasticizing screw inside the barrel is subjected to significant wear due to the abrasive nature of plastic materials. To counteract this, manufacturers use durable, wear-resistant materials to construct the barrel, enabling it to withstand repeated friction and contact with the plasticizing screw. Hardened steel or bimetallic alloys enhance the barrel’s resistance to abrasion, extending its lifespan and reducing the need for frequent replacements or maintenance.

Just like the screw, the barrel must be made of high-quality materials to meet working requirements. It should have high temperature resistance, wear resistance, corrosion resistance, and high strength. These materials should also possess good machinability and heat treatment properties. In addition to 45 steel, 40Cr, and 38CrMoAl, the barrel can also be made of cast steel and ductile iron. The feeding section with a bushing can be made of high-quality cast iron.

In recent years, with the development of high-speed extrusion and engineering plastics—especially the extrusion of glass fiber-reinforced plastics and plastics containing inorganic fillers—higher requirements have been set for the wear resistance and corrosion resistance of the barrel. Xaloy alloy, developed in America and Belgium, is a new kind of wear-resistant and corrosion-resistant material that has been widely used abroad. This material has a low melting point, is hard, has good fusibility with steel, good machinability, and good casting performance, with no casting stress. Even if it is bent after casting, it will not flake off.

When applied to the barrel, this powder-like Xaloy alloy is heated together with the barrel at high temperatures. Due to its low melting point, it can melt into a flowing state at about 1200°C. At this temperature, the barrel rotates at high speed, and the enormous centrifugal force produced by the molten Xaloy causes it to cast onto the inner wall of the red-hot barrel to a thickness of about 2 mm. After cooling, it is ground to about 0.20 mm, which can meet the requirements of a general barrel.

It is reported that the hardness of a type of Xaloy alloy produced in Belgium can reach Rc58-64. At 482°C, the hardness does not decrease significantly, and its corrosion resistance is 12 times higher than that of nitriding steel.

Injection Molding Barrel Structure

Integral Barrels

Integral barrels are processed as a single piece. This structure ensures high manufacturing and assembly accuracy and simplifies assembly work. It facilitates the installation, assembly, and disassembly of the heating and cooling systems. Additionally, heat is relatively evenly distributed along the axial direction. However, this type of barrel requires higher processing and manufacturing conditions.

Combination Barrels

Combination barrels are composed of several barrel sections. Experimental extruders and vented extruders often use combination barrels. The former facilitates changing the barrel length to adapt to screws with varying length-to-diameter ratios, while the latter includes an exhaust section. In some cases, the use of combination barrels benefits small and medium-sized factories by allowing localized material and processing. However, combination barrels require high machining accuracy. Each section is connected with flange bolts, which disrupts uniform heating and increases heat loss. Additionally, setting up and maintaining the heating and cooling systems can be inconvenient.

Bimetallic Barrels

To meet material requirements while saving valuable materials, many barrels are inlaid with an alloy steel bushing inside a base of general carbon steel or cast steel. When the bushing wears out, it can be removed and replaced. The bushing and barrel must be well-matched to ensure that heat conduction along the entire barrel wall is not affected, that there is no relative movement between the barrel and the bushing, and that the bushing is easily removable. Appropriate fit precision is essential, and some factories use specific fit methods.

IKV Barrels

Longitudinal grooves are set on the inner wall of the feeding section of the barrel to improve the solids conveying rate. According to solids conveying theory, one method is to increase the friction coefficient of the barrel surface, while another is to increase the cross-sectional area of the material at the feeding port. Creating longitudinal grooves on the inner wall of the feeding section and tapering the inner wall near the feeding port are embodiments of these methods.

Determination of Barrel Wall Thickness and Strength Calculation

Determining the Wall Thickness of a Plastic Molder Barrel

Barrels are rarely scrapped due to insufficient strength; more commonly, issues arise from corrosion and wear. The decision regarding barrel wall thickness, besides considering strength, also takes into account craftsmanship and the thermal inertia of the barrel structure. The wall thickness determined by these factors is often larger than what would be calculated purely based on strength considerations. Since there is no well-established method for calculating barrel wall thickness based on heat transfer characteristics, most wall thicknesses are determined through empirical statistical analogy and then checked for strength.

Strength Calculation of Injection Mold Machine Barrels

The strength calculation of the barrel is conducted according to the principles for thick-walled cylinders, so no further discussion is included here. Note: When the barrel is made of a brittle material, the first strength theory can be used for calculation. For plastic materials, the fourth strength theory should be applied.

Requirements And Functions Of Various Accessories For Injection Molding Barrels

Three Small Parts of the Screw Head

The three small parts of the screw head play crucial roles in sealing, kneading, plasticizing, and other functions within the screw assembly. They are an essential component. Many quality issues with plastic products are closely related to these three small parts. Often, neglecting the details of these parts can significantly increase the scrap rate of plastic products and may even force production shutdowns for maintenance, leading to substantial production losses. The overall surface of these three small parts must be smooth. Except for the assembly areas, any visible parts should not have right angles, acute angles, or dead angles; transitions should be smooth. The size of the smooth radius (R) depends on the specific situation because wrong angles can easily crack and accumulate material, disrupting the smooth flow of raw material. Over time, this can lead to black spots and yellowing, with these three small parts being particularly prone to yellowing. Issues with materials like PC and PMMA often result from abnormalities in these parts.

The Two Ends of the Rubber Ring

This design is also very important. Many injection molding machine manufacturers now design the joint surface of the rubber ring and the meson to be flat, without a slope. This design choice has two disadvantages:

- Planar contact has a smaller surface area compared to inclined contact, leading to a significantly shorter service life.

- A flat junction between the meson and the screw head creates a dead angle where raw material can accumulate, leading to black spots and yellowing over time. An optimal slope is 30 degrees. A 15-degree slope is insufficient and can cause material accumulation, while a 45-degree contact surface is less likely to accumulate material but may cause the rubber ring to burst during injection.

- The gap between the left and right sides of the rubber ring should be moderate. Depending on the raw material being processed, choose a larger or smaller gap accordingly. A gap that is too large can lead to instability in glue injection for large machines producing thin-walled products, while a gap that is too small can cause rattling noises during production due to unsmooth discharge.

Screw Head

The surface of the threaded part does not need to be as hard as other parts. Excessive hardness can cause the thread to wear out and lose strength. It is recommended to use nitrogen protection before heat treatment or to process the thread after nitriding. The undercut of the threaded part should preferably have an arc-shaped radius (R) rather than being cut directly with a right-angle tool. This design choice improves stress distribution, as many screw head fractures occur in this area.

Properties of a Plastic Injection Molding Barrel

Processing on the Overall Blank

A plastic injection molding barrel is manufactured from a single overall blank. This construction ensures high precision in manufacturing and assembly. It simplifies the assembly process and facilitates the setup, installation, and disassembly of the heating and cooling systems, while also ensuring reasonably uniform heat distribution along the axial direction. Naturally, this type of barrel requires more stringent processing and manufacturing conditions.

A Single Barrel Made of Barrel Combinations

This refers to a barrel constructed from multiple pieces. A multipurpose combo barrel might include an experimental extruder and a vented extruder. The experimental extruder allows for changes in the barrel length to accommodate screws with different aspect ratios, while the vented extruder is used to configure the exhaust section. Combining barrel segments enables localized material acquisition and processing, which is advantageous for small and medium-sized industries. However, such a combined plastic injection molding barrel requires precise machining.

Bimetallic Barrels

Many barrels are designed with an alloy steel bushing inlaid inside a base made of regular carbon steel or cast steel. This design not only meets the material requirements of the barrel but also conserves valuable materials. When a bushing wears out, it can be removed and replaced. It is crucial that the bushing and barrel are perfectly matched to ensure that heat conduction across the entire barrel wall remains effective. There should be no relative movement between the barrel and the bushing, and the bushing should be easily removable. This necessitates careful attention to fit accuracy.

Injection Molding: Improving Barrel Temperature Measurement and Control

Let's start by improving barrel temperature measurement and control. Barrel-zone temperatures significantly influence melt temperature. It is widely accepted that approximately 20% of the energy required to melt the plastic comes from the heater bands, making them crucial for startup. So, what can you do to ensure that you are reading the barrel temperature correctly?

Measuring barrel temperature seems straightforward: use a thermocouple to measure the steel temperature and control the heater band with an ambient-temperature-reference PID (Proportional Integral Derivative) controller. There is nothing new here. You can use J-type or K-type thermocouples (TCs), as both provide similar accuracy (the greater of 2.2°C/4°F or 0.75%) across the temperature range most molders operate in: 23°C to 490°C (70°F to 900°F). Both J and K types can measure temperatures well above 600°C (1100°F).

Ensure that the wires are in good condition—without splices—and routed so that molten plastic does not come into contact with them. It is frustrating to see that 95% of the machines I encounter have the TC and electrical wires hanging down from the barrel, with 60% of the time having molten plastic hanging from them. This results in significant costs due to downtime, wire replacement, safety issues, and inconvenience. There is no reason you cannot take some time to secure the wires on the non-operator side. Doing so will save you more time later, so it is worth addressing now.

Our Factory

Suzhou Kotler Precision Machinery Co., Ltd is located in the city of Suzhou, "where there is a paradise above and Suzhou and Hangzhou below." Kotler is located in the southwest of Suzhou city, west of the Taihu scenic area 2 km, south of Dongshan scenic area, north of Suzhou ring expressway 1 km, and east of Suzhou central elevated road. It is an important manufacturing base in east China with convenient transportation. The superior transportation position is an important reason for setting up the factory.

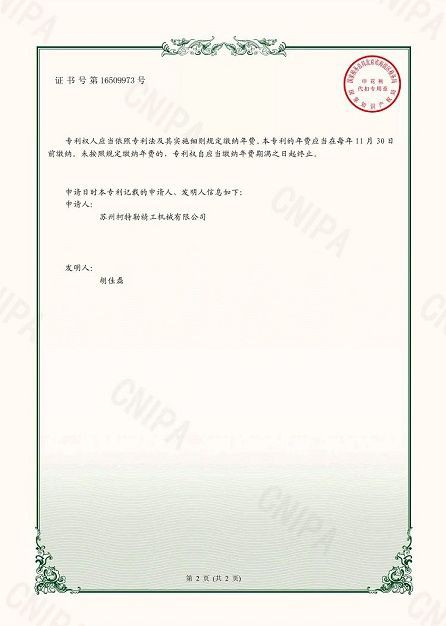

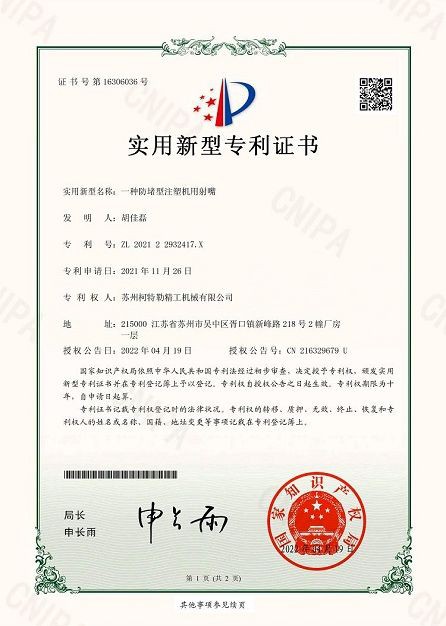

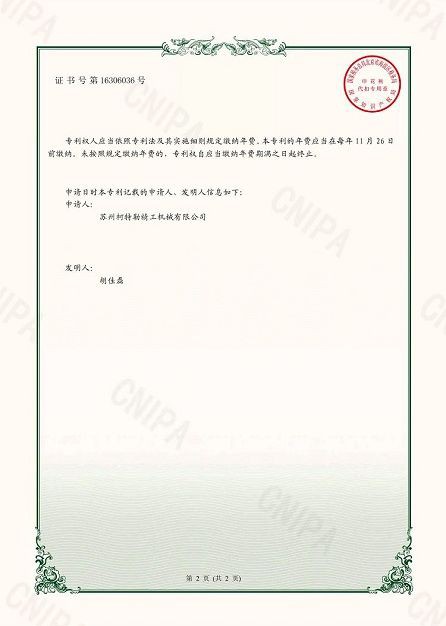

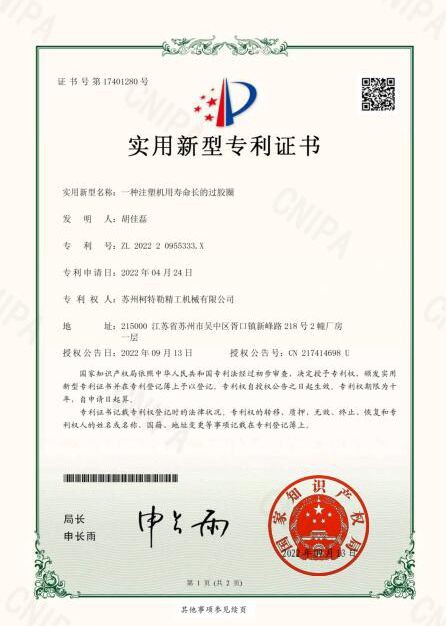

Our Certifications

FAQ

We're well-known as one of the leading barrel manufacturers and suppliers in China. Welcome to buy high quality barrel in stock here and get quotation from our factory. Contact us for customized service.

feed screws for injection molding, screw type injection molding machine, Extruder screw for PBT foam extrusion